Dear Eartha,

I recently read about a new hostel-style hotel being built in Silverthorne and the owner’s goal of diverting 80-90 percent of the old building materials away from the landfill. Can you tell me more about “green” demolition?

Jake, Silverthorne

Jake, let me first start by saying this is super exciting news for Summit County. It’s hard work to meet this diversion goal, and when someone takes the extra effort, it really means that they care about the environment.

In the specific example of “The Pad” in Silverthorne, the duo of developers, Lynne Parrish and Rob Baer, are not only repurposing 16 prefabricated shipping containers to build the framework of the project, but they also plan on salvaging old building materials from the existing Robinson Dairy into the new hotel. What they can’t use will be donated to nonprofit organizations that resell old building materials from demolitions. While this scenario isn’t completely zero-waste — anything not suitable for recycling or donation will go to the landfill — as you mentioned, Jake, the goal is to drive 80-90 percent of the materials which is still an impressive accomplishment.

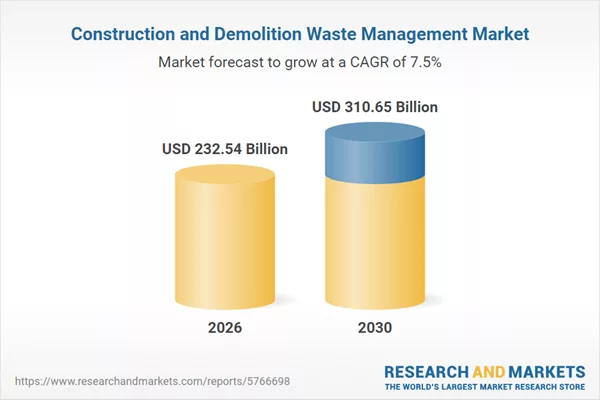

How will Lynne and Rob get there? Green demolition — or deconstruction — is performed by dismantling an existing building (such as the Robinson Dairy) so that as many of its elements as possible can be recycled or reused rather than going to landfills. According to the U.S. Environmental Protection Agency, 534 million tons of construction waste were generated in the United States in 2014 – more than twice the amount of municipal solid waste. Now just imagine if 80 percent of this was diverted from our landfills and repurposed into other projects. That would be 427 million reused tons of material and only 107 million tons in our landfills.

While Rob says that recycling will be the most common use for the old building materials, he anticipates that deconstruction will add about $10,000 in upfront costs. However, anything that can be salvaged or reused will go into construction of the new hotel. Things like wood floors and beams, concrete, steel, windows and doors, tiles and carpeting, aluminum siding, roofing materials, plumbing and lighting fixtures, pipes and bricks can (and will) be reused. By doing so, Lynne and Rob will offset some of the deconstruction expenses. They’ll also save money by not paying landfill fees, and they’ll receive tax deductions for donated items.

Green deconstruction can take longer than traditional demolition, so why go through this extra effort? For Lynne and Rob, the ultimate goal is to be kind to the environment. Here are a few ways deconstruction is eco-friendlier than demolition: Green demolition uses fewer natural resources and produces fewer greenhouse gas emissions by eliminating the manufacturing and transportation of new material as well as processing of demolished material.

Deconstruction helps keep materials out of landfills, theoretically cutting construction landfill use in half in the United States alone. Repurposing these materials away from landfills ultimately benefits air, soil and water quality while also extending the life of the landfill. I see the process of deconstruction as an extremely valuable next step toward resource conservation in our mountain community. My hope is that other builders stand up and take notice of what Lynne and Rob are preparing to do, and hopefully this becomes a common practice in years to come.

Ask Eartha Steward is written by the staff at the High Country Conservation Center, a nonprofit organization dedicated to waste reduction and resource conservation. Submit questions to Eartha at in**@*********************on.org.