The demolition industry is entering a new era — one defined by technology, precision, and sustainability. What once relied solely on brute strength and heavy machinery is now driven by automation, artificial intelligence (AI), data analytics, and eco-conscious engineering. These advancements are reshaping how we plan, execute, and evaluate demolition projects across the world. As cities grow smarter and sustainability standards tighten, demolition is no longer about tearing things down — it’s about rebuilding responsibly, reducing waste, and harnessing innovation to create safer, cleaner worksites. The Shift Toward Smart Demolition

Traditional demolition once depended heavily on manual labor and experience. Today, it’s transitioning toward data-driven planning and precision automation. Engineers and project managers now rely on 3D modeling, digital mapping, and AI-assisted analysis to predict how structures will react during dismantling. This shift reduces human error and enhances control, allowing for safer teardowns and cleaner site outcomes. “Smart demolition” represents a merging of technology and craftsmanship — where every movement is guided by information, not guesswork.

How Automation Is Changing the Job Site

Automation is transforming demolition from the ground up. Remote-controlled excavators, robotic arms, and autonomous loaders are now capable of performing high-risk tasks without putting human lives in danger. These machines can navigate confined areas, cut steel with pinpoint precision, and separate recyclable materials in real time. Beyond safety, automation improves efficiency, enabling crews to complete projects faster and with fewer interruptions. As robotic technology becomes more accessible, automated demolition equipment will become standard across large-scale commercial and industrial sites — reducing labor strain and increasing productivity.

Artificial Intelligence and Predictive Safety Systems

AI isn’t just a buzzword in demolition — it’s becoming an integral safety tool. Artificial intelligence systems are now being used to predict hazards, monitor machine performance, and even detect unsafe structural shifts before they happen. With the help of machine learning algorithms, site managers can analyze thousands of data points in real time — from vibration patterns and dust levels to temperature and structural tension. These predictive systems give demolition professionals a new level of foresight, reducing accidents and downtime. In the coming years, AI-driven analytics could make reactive safety procedures a thing of the past, replacing them with preventative intelligence that keeps every job site under control.

The Rise of Drone-Assisted Demolition Surveys

Drones have revolutionized how demolition sites are surveyed, monitored, and documented. Instead of relying solely on manual inspections or scaffolding-based assessments, high-resolution drones can now scan entire structures within minutes. They collect detailed aerial imagery, generate 3D models, and identify potential weak points before equipment even arrives on-site. This improves safety, saves time, and drastically reduces the margin for error in structural analysis. Beyond planning, drones are also used during active demolition for real-time progress tracking and post-demolition verification, ensuring the work aligns perfectly with engineering plans. Drone technology has turned once-dangerous site evaluations into safe, data-driven operations.

Digital Twins and Virtual Site Modeling

One of the most groundbreaking innovations in modern demolition is the rise of digital twins — virtual replicas of physical structures. Using laser scanning, AI mapping, and advanced software, demolition teams can simulate how a building will collapse, where debris will fall, and how to sequence each step safely. These virtual models enable contractors to test multiple demolition methods before choosing the most efficient and secure option. In the future, we’ll see digital twins integrated directly with on-site equipment, allowing machines to “see” what operators see and adjust actions dynamically. This not only saves time and resources but also sets a new benchmark for precision demolition.

The Push for Zero-Waste Demolition

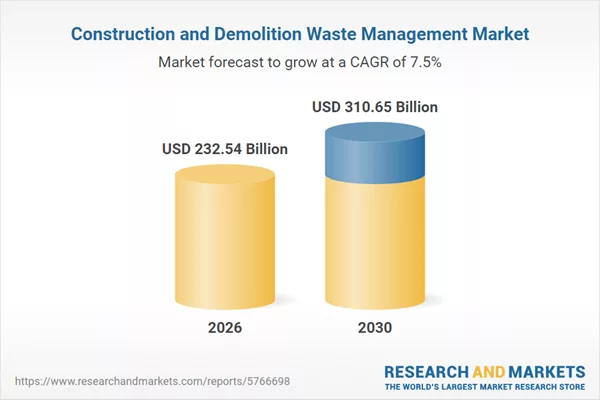

The future of demolition is as much about what’s preserved as what’s removed. A growing global initiative toward zero-waste demolition is driving contractors to salvage, recycle, and repurpose materials instead of sending them to landfills. From crushed concrete being reused as base material to reclaimed metals and lumber finding new life in construction, sustainability has become a cornerstone of modern demolition strategy. AI-assisted sorting systems are now being developed to automatically identify recyclable materials during teardown, ensuring that waste diversion happens in real time. As regulations tighten and sustainability becomes a public expectation, zero-waste demolition will define the next generation of responsible contractors.

Sustainable Equipment and Electric Machinery

As construction industries worldwide reduce their carbon footprint, demolition is following suit with electric-powered equipment and hybrid hydraulic systems. Electric excavators, loaders, and breakers produce significantly lower emissions while still maintaining power and efficiency. In urban environments, this advancement also reduces noise pollution — a major benefit for residential and commercial areas. Battery technology is improving rapidly, allowing heavy machinery to operate for longer durations on a single charge. This not only enhances environmental responsibility but also cuts operational costs in the long term. Sustainable machinery isn’t just the future — it’s already becoming the industry standard for leading demolition companies.